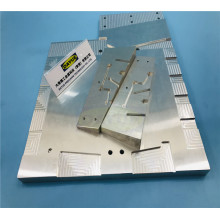

Basic Info

Model No.: CM-013

Click on the follow link to find out more information: https://www.bldcncmachining.com/cnc-milling-machining/

Company Info

- Company Name: Hong Kong RYH CO., LTD

- Representative: Bill Sun

- Product/Service: CNC Machining , CNC Machining Parts , Machining , CNC Milling , CNC Turning , Machining Parts

- Capital (Million US $): 5000000RMB

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 46

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: A5building, SongbaiRD3055, Guangming District

- Contact Person: Mr. Sun

- Tel: 86-0755-23502940

Premium Related Products

Other Products

Hot Products

Carbon Steel Mesh for Dining TablePlastic Oven Knob, Plastic Knob Ytp-01Bakelite Knob Oven Knob (YTB-02)Zinc Aluminum Alloy Knoboven KnobElevator Traction Machine Damping PadAluminum Die Casting MoldHigh Quality Outdoor LED Road Light Street LightDie Casting for Camera Frame (EEP-007)Plastic Injection Moulding, injection plastic moldPrecision Brass machining parts, CNC machining parts, CNC machining manufacturersSheet metal fabrication, metal stamping, metal stamping partTaiwan OEM die casting parts, custom made zinc die casting, die castingInvestment casting, stainless steel investment castingPrecision powder coating partsTaiwan CNC machining, precision CNC machining parts, cnc machined aluminum partsAluminum die casting parts, die casting service, die casting